|

|

LC900 DATA TABLE

|

|

Cartridge number

|

Colour

|

OEM full weight

|

Empty weight from printer

|

True empty weight

|

Ink delivered

|

Recommended fill

|

OCP Ink ref

|

|

LC-900Bk

|

Black

|

41.20g

|

22.80g

|

n\a

|

18.40g

|

22ml

|

BKP45

|

|

LC-900

|

Cyan

|

31.45g

|

20.25g

|

n\a

|

11.20g

|

12ml

|

C92

|

|

LC-900

|

Magenta

|

30.45g

|

21.25g

|

n\a

|

9.20g

|

12ml

|

M88

|

|

LC-900

|

Yellow

|

31.20g

|

21.20g

|

n\a

|

10.00g

|

12ml

|

Y77

|

Brother’s LC-900 series cartridge is easily refilled using Promax Plug Valves*.

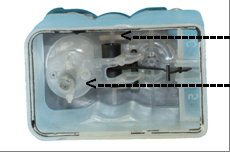

The construction of this cartridge is fairly simple. But it is difficult to refill due to the construction of the seals on both the venting point and the delivery point. These seals, which have a soft thin silicon rubber body, are very sensitive to pressure, and will break if any more than the slightest pressure is applied to them.

One of the major causes of failure in this group of cartridges is ink blocking the venting valve, yet it is impossible to see this without first disassembling the cartridge, which will also render the cartridge useless.

This ink usually gets into the venting upstand after the customer has removed it from the printer so he can bring it to you for refilling.

The Professor can hear you saying “Well why doesn’t it happen to new OEM cartridges then?” Simple – it’s due to air pressure, surface tension, ullage and orifice. No, this is not going to be the subject of another lecture. If you really want to know why, then email the Professor at: professorpromax@professorpromax.com.

There are other causes of ink getting into the valve. These include under-filling, ink foaming during refilling, over-filling and extreme variances of temperature if the cartridge is not stored in an upright position.

Therefore care must be taken by you not to overfill these cartridges, otherwise THEY WILL FAIL to function in the printer due to blockage of the venting valve, rendering the cartridge unable to aspirate.

This same problem may also damage the print head if back suction is created, which causes air to ingress into the printhead through the jets. Result, one unhappy customer, and one huge repair bill for you, SO BE WARNED.

NOW FOR THE GOOD NEWS. Using the Promax Plug Valve* to refill this group of cartridges will ensure consistently good results.

The plug valve* prevents ink foaming during refilling, and most importantly, it clears the venting valve of any ink liable to cause problems later while the cartridge is being refilled, by expelling the ink from the valve.

|