|

|

||||||||||

|

Promax Imaging Ltd 14-16 Uttoxeter Rd Tel: Fax:

|

||||||||||

|

|||||

|

|||||

|

|||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

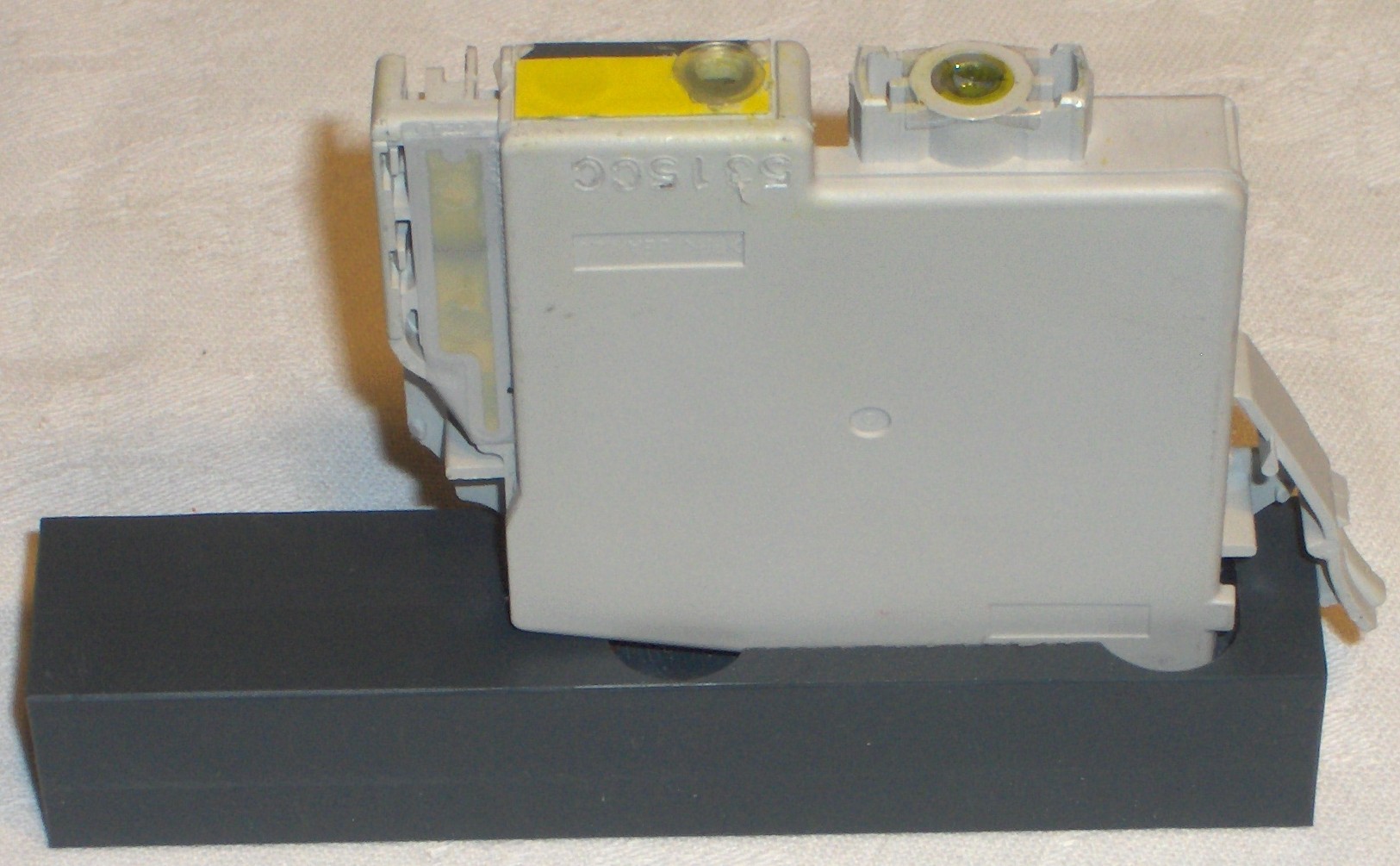

Place the Plug Valve* in the filling hole and firmly press it in. Please ensure it is pushed all the way home to properly seat and seal the Plug Valve* in the cartridge. |

|

|

|

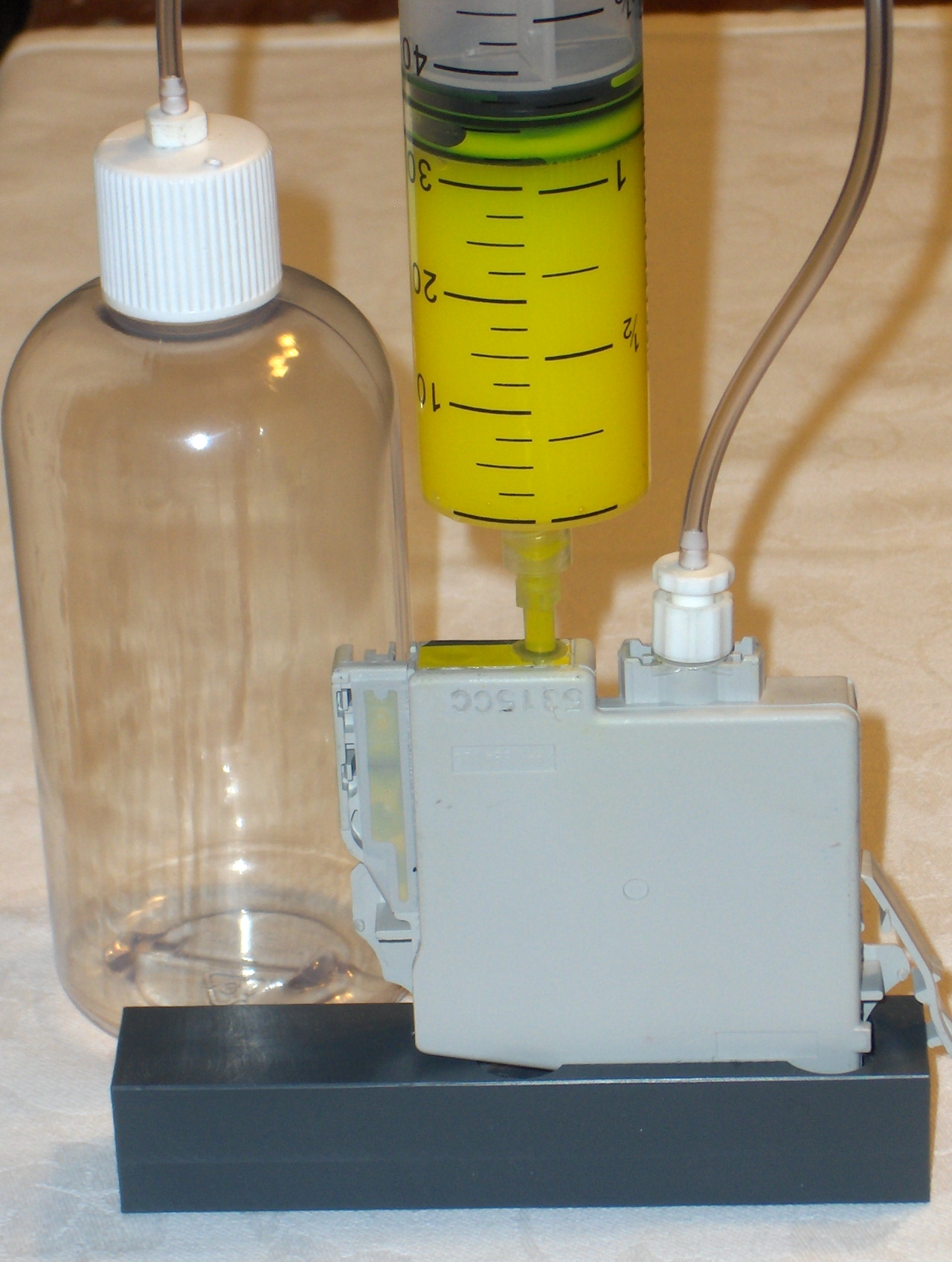

It is good re-filling practice to remove all residual waste ink before refilling a cartridge. The refilling process utilised with the Promax Plug Valve* takes care of this job as you refill the cartridge. However, if you want to recover the excess ink used in the refilling process, this is what you do. Follow the instructions below, using an empty syringe filled with air, BUT hold the cartridge the other way up. Steadily inject the air into the cartridge. This expels the residual waste ink. Change the waste bottle for a clean one and follow the refilling steps below. The bottle now contains your fresh excess ink which can be re-used. If you are refilling a number of cartridges at a time, it is a good idea to purge the waste ink from them all first. Remember to wipe the nipple of the waste line before plugging it into a different colour cartridge to prevent contamination of the colours. |

|

|

|

When the ink enters the cartridge the old ink is expelled through the waste pipe, followed by the air. After all the air is expelled, a mixture of ink and air will be expelled, followed by pure ink. This ensures the cartridge is correctly primed. Remove the waste pipe and syringe from the cartridge and wipe away ink drops. Ensure the black seal in the delivery nozzle of the cartridge is seated fully home by pressing on it. Reset the chip using a seven point chip resetter. The cartridge is now ready for use. RE-LABEL THE CARTRIDGE TO MAKE IT CLEAR IT IS A REMANUFACTURED CARTRIDGE, PREFERABLY COVERING THE OEM LABEL. |

|

22nd February 2007 |

| [Home] [Press Releases] [Pricing] [Lectures] [Testimonials] |

|

Copyright 2006, 2007 Promax Imaging Ltd. All references to trademarks and registered names on this website are for identification purposes only and do not imply a relationship with any such manufacturer. |